Mixers

Feed Milling Mixers

Optimal mixing of feed ingredients.

- Efficient and speedy operations since they have the ability to produce 30 parties of final product per hour

- Ability to incorporate multiple liquid supplements

- Self-cleaning and easy to maintain

- Double sealing of bottom damper

See the video below to find out exactly how the Andritz mixers are able to achieve all the above attributes!

ΑΝΑΜΕΙΚΤΗΣ (MIXER) ΧΡΟΝΟΣ ΑΝΑΜΕΙΞΗΣ 75-90 ΔΕΥΤΕΡΟΛΕΠΤΑ

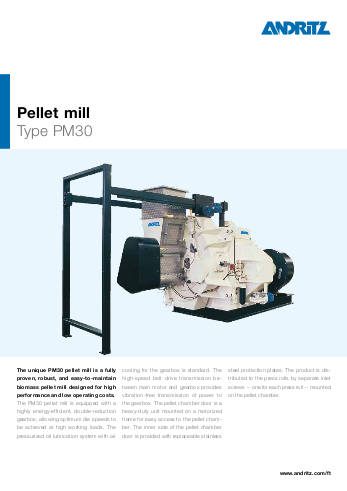

Pellet Mills

Pellet Mills for Feed Milling and Biofuel Production

High Efficiency and Production Capacity

The Andritz pellet mills offer high production capacity while being cost and energy efficient operations thus maximizing the return of the plants.

Uniquely easy to maintain and clean, they are able to produce a highly hygienic end product.

FeedMax G Series

- Smaller in size and more compact, which makes them easily incorporated into different production lines

- Internal lubrication sprinkler which maintains the press and ensures its longevity

- Excellent distribution of ingredients in every pellet due to the one-piece adjustable feed plough design, which guarantees quick and easy re-configuration and thus homogeneous distribution of ingredients on the die ring and Roll Shells

- Designed for increased lifecycle, all components that come in contact with the ingredients are made of stainless steel

- Easy replacement of die rings

- Gear driven and V-belt models available

Gear-driven Pellet Mill

Indicatively, the procedure of replacing a die ring takes only 10 minutes.

Finally, their uniquely efficient design allows them to operate non-stop on a 24/7 basis throughout their lifespan.

V-Belt Pellet Mill

Read more about the pellet mills in the product guides below.

Hammer Mills

Hammer Mills

High Performance with Efficient Use of Raw Materials

The Andritz hammer mills are the result of the year-long experience and studies conducted by the firm. Achieving high performance and efficiency in a compact design, the different models of hammer mills are able to produce all ranges of products, from coarse to super fine granules.

Optimill Series

Basic Features:

- Milling resulting in coarse granules – optimal size of final product

- Patented closed rotor design which ensures 20% reduction of energy consumption

- 1,500-1,800 rpm

- Low noise

Multimill Series

Basic Features:

- Ability to grind raw materials into super fine granules

- Small screen area

- Ability to maintain low temperatures during production thus preserving the nutrients of the feed.

- Energy efficiency

- 3,000 – 3,600 rpm

Coolers

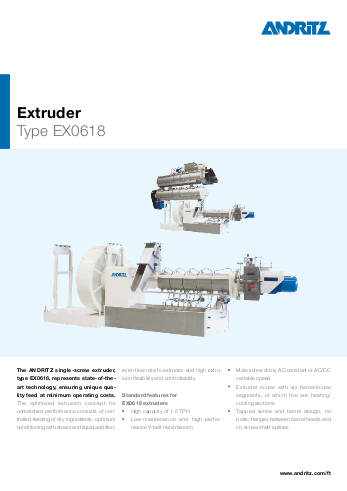

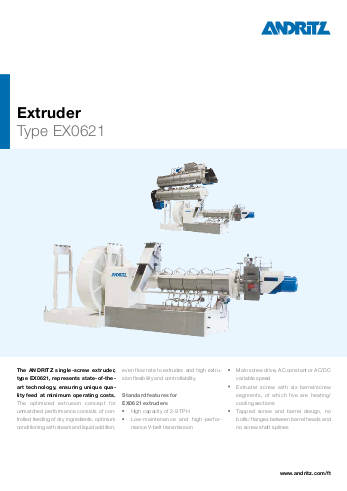

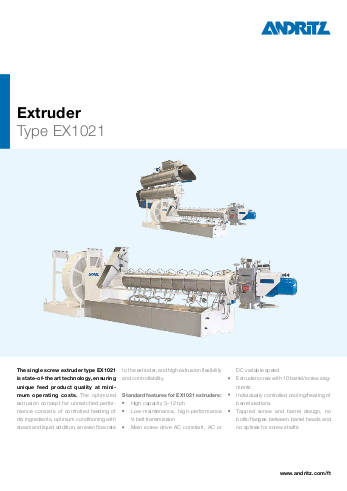

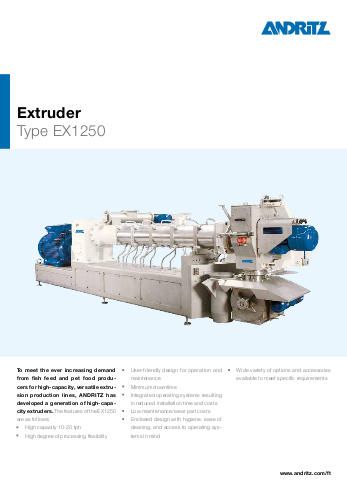

Extruders

Extruders

Designed for Pet Food Production

ANDRITZ offers a wide range of Extruders which, when combined with other equipment, are able to cover every diverse need a client might have.